Whether you have a motorcycle, outboard engine, some sort of powersport vehicle or an ATV, boring an engine’s cylinders is an important step in the engine rebuilding process and is an economical way of repairing damaged and worn out cylinders in engine blocks. The process (if done properly) literally restores your engine block back to factory specifications (or larger with big-bore kits) giving you tight tolerances and restored horsepower and compression for a fraction of the money it would cost for a new engine or powerhead in most cases.

So what is cylinder boring? Cylinder boring is a process where a specialized machine and tooling removes the damaged material from the cylinder walls by spinning a special carbide tool inside of the cylinder. This tool cuts away the damaged area and smooth’s the cylinder walls so that the piston can move up and down with minimal friction and allows for maximum compression.

Why and when should you bore/sleeve your engine block?

Before talking about the process of cylinder boring I would like to talk about when and why it may be necessary. Obviously an engine seizing would indicate that the engine block may need to be bored or sleeved, but also loss of horsepower and/or compression would also show that it may be time to repair the cylinder and replace the pistons and rings.

When talking about ATV’s, powersports and motorcycles there are many scenario’s that cause damage to the cylinder walls. One of the main causes of engine seizure or loss of compression is sand in the air filter that gets into the engine. It usually leaves vertical scratches all over the piston and cylinder walls. We have seen people bore out there cylinder and then put the engine all back together and forget to clean out the air box and burn up the brand new piston and sleeve/cylinder in minutes.

The other common situation is not properly breaking in the engine or properly warming up the engine. When you turn on your engine and start racing it the piston that is moving up and down at a high rate of speed will create friction and therefore heat up. If the pistons or rings heat up to quickly they may crack or break into pieces leaving deep gouges in the cylinder walls.

- Damaged piston in any way may be reason enough to re-bore your cylinder.

- Vertical scratches that you can feel on the cylinder wall is reason enough to bore your cylinder.

- Any piston seizing is a reason to bore your cylinder.

- Any apparent piston damage or vertical lines are an indication that a cylinder should be bored.

- Excessive piston to cylinder wall clearance (measured with a feeler guage)

- Excessive ring end gap (over .025 inch)

Mounting the engine block:

The first step in the cylinder boring process is mounting the block in the boring bar. A flush mount is necessary in order to attain a perpendicular bore. A boring bar is a specialized piece of machinery that is made for the cylinder boring process. Mounting the cylinder on a milling machine or lathe makes it difficult to ensure the powerhead block is mounted flush.

The cylinder boring process:

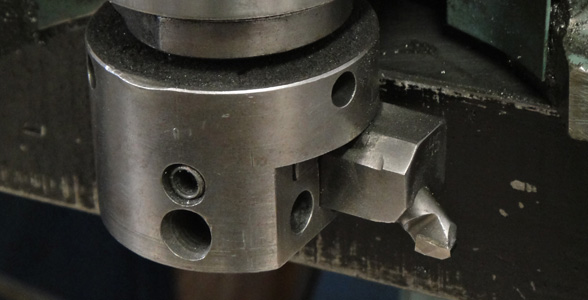

The boring process requires a very sharp carbide cutting bit for a clean and true bore. Depending on the amount of material that needs to be taken out of each cylinder to clean up the damaged or worn bore has a great deal to do with how many passes needed to finish the job. Usually, with a standard bore there are between 3-5 passes required to get the desired clearance. With a cylinder re-sleeve it may take as many as 10 passes to remove the old sleeve and another 3-5 passes to achieve the desired clearance.

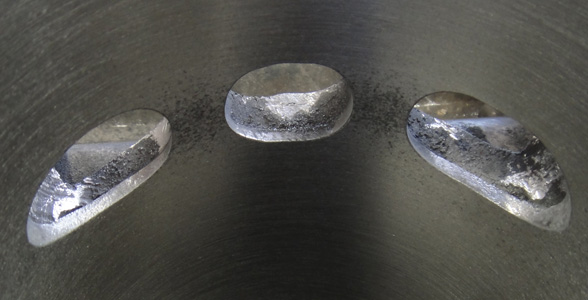

Chamfering ports (2-strokes):

After the actual boring of the cylinder on 2-stroke engines, it may be necessary to chamfer (to remove) the port edges. If the edges of the port holes are too sharp it may damage the piston rings as the piston moves up and down. The rings will then in turn damage the cylinder walls and defeat the purpose of boring the cylinder. With the use of a finished ball hone, the 2-stroke ports will have sufficient chamfering or rounding of the edges. A small amount of material is all that needs to be removed. All you’re trying to do is dull the sharp edge.

Honing Tools:

There are a few different types of hones on the market but paddle hones (also known as stone hones) are the preferred style. These hones are size adjustable with a screw that pushes the paddles outward toward the cylinder wall allowing the operator to add tension as needed.

Fine finishing stones on the paddles of the hone give the bore a smooth finish with proper crosshatching of the cylinder. It should be done after the cylinder is bored as it is the process that attains the final finish and size of the bore.

Many times, a ball hone is the preferred hone for 2-stroke engines as it will usually chamfer the ports in the process.

Additional factors to be aware of:

Most machine shops with the proper tooling (ie: boring bar) to do cylinder boring will be happy to show off their equipment. If the shop only shows you a honing tool then take your business elsewhere. A hone is not a precision tool and removing large amounts of material with a hone will more than likely get the bore out of square and will sometimes cause irreversible damage to the cylinder.

A boring bar is a precise machine specifically made for boring engine block cylinders. They are expensive and many shops feel that a lathe or milling machine will suffice. Although these machines do very detailed work, in most cases they will not accurately bore the cylinder to the desired clearance.

After picking up your block from the machine shop, make sure to clean your block thoroughly. You don’t want any cast iron dust or debris left on the cylinder walls or in the block when re-assembling your powerhead.